Years of successful operation of the enterprise

55 +

Production Units

4 500 +

Employees in the company's staff

1 800 +

Factory partners

100 +

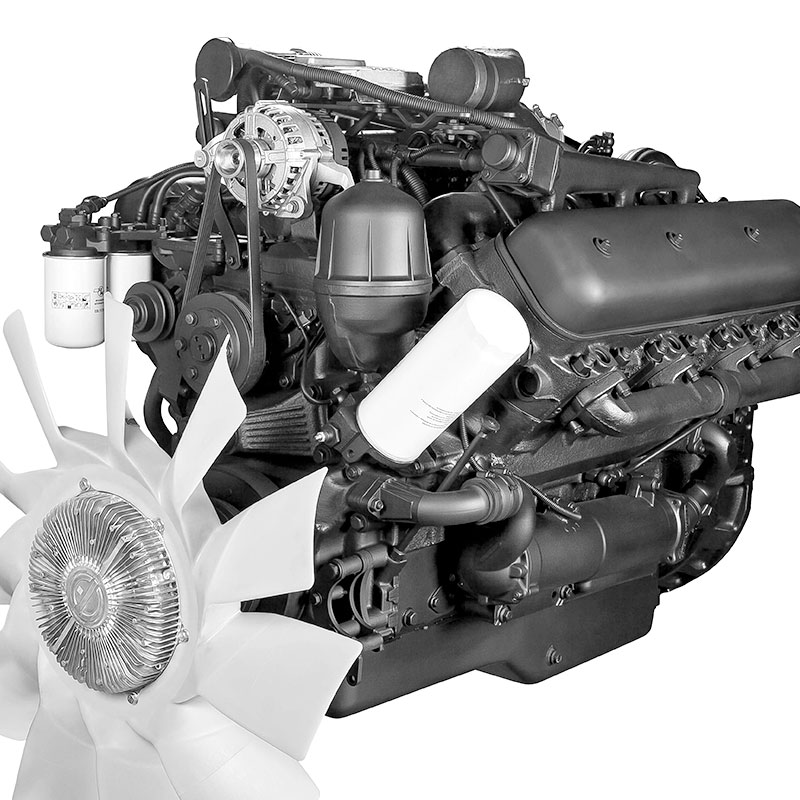

ADVANCED TECHNOLOGIES AND EQUIPMENT

High-precision equipment, unique technologies and developments allow us to reduce production costs while maintaining high product quality

Unique production

The only specialized plant for the production of all parts of the cylinder-piston group in Russia and other CIS countries

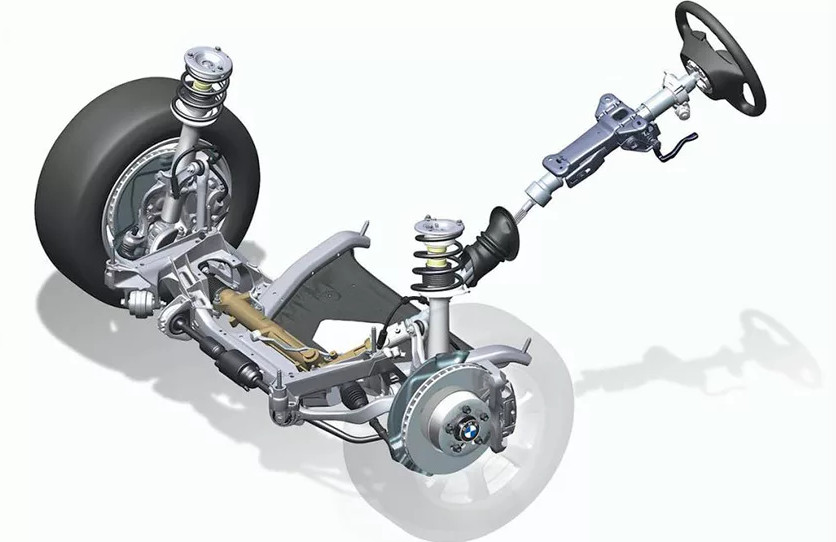

URBAN-FORMING ENTERPRISE

The Company makes a significant contribution to the development of the economy of the Russian Federation and is a key taxpayer and employer in the Kostroma Region. The company employs more than 2000 people. The team is tightly integrated into the cultural and business environment of the region: employees participate in many "external" events under the "flag" of the company, off-site events of business organizations and authorities are held at the sites of the KZA itself. [Not Agreed]

ABOUT COMPANY

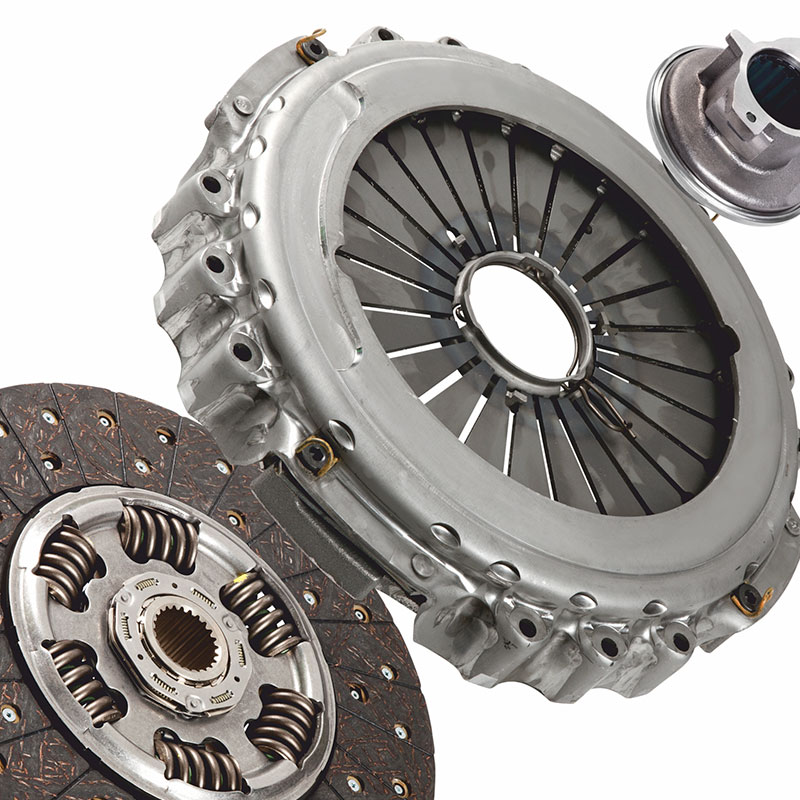

Russian world-class manufacturer

High-precision equipment and unique technologies allow KZA to bring products to the market that meet international quality standards.

The company is certified according to ISO: 9001 (Quality Management System Organization).

-

55 +

years of quality

-

40 countries

geography of supplies "Motordetal"

-

25 million

units of finished products per year

-

Official supplier

engine factories and automotive companies

News

All news